Years of scouring the internet has really given me some deep inspiration/admiration for extreme purpose build machinery I can read group B restoration threads for hours on end or flip through pictures of early Porsche 993 test mules or cup cars. There is something extremely elegant the way a meticulous approach and a singular goal pare road cars to their most potent form. Stark, but not wanting. clean. direct. simple.

Funny thing is, typically the more you take out of a road car the more you have to modify things to stand on their own. Road cars are not inherently modular; everything is packaged for ease of manufacture and installation at the factory. Once you move or change a few things suddenly youve thrown something else out of wack. Its always a mixture of "while your in there" and "the head bone is connected to the neck bone..."

So as I'm busy tearing the car apart and making plans i've also been doing research and reading up. As I alluded too previously, the intent of this car is to be tracked hard often with the minimum of worries. The lessons ive learned building, reading about and tracking cars for the past 15 years have taught me, Simplify, overbuild, replace and update as needed.

"buy it right or buy it twice." the heartache of something cheap failing at the track is the worst kind. I'd rather be driving, not wrenching.

i think even before the car was confirmed as on the shippers truck I started buying parts. I didn't go crazy because I still had no idea what was actually coming on the car but I did buy a few things that I knew id need from the pictures I was sent.

I already knew that i wasn't going to keep the USDM boat anchors. I found a Goodline/runfree front bumper off club 4ag. I had actually bought a bunch of corolla parts from this seller years prior for my old car. When he saw it was me walking up his driveway all these years later he just laughed and said "its okay i'm on like my 10th 86 myself"

the bumper came as unpainted fiberglass, I did some minor body work on it and plasti dipped it black-- This was back before I was headfirst into the build and I thought I was going to keep the car blue as it came. Black bumper on a blue car was an easy solution to the white unprepped fiberglass

Once I realized what I was in for on the build as a whole and that the car would eventually need full repainting I had to spend an afternoon in the garage peeling plastidip for HOURS. Now the bumper is back to white and can be painted to match whatever it is I settle on.

Heres a picture I took of my parts pile a few weeks ago, im still getting deliveries almost every other day. Whats been the toughest is keeping track of the smallish things. they tend to be the most expensive and easy to misplace.

A quick run down- right to left of the above picture.

I bought every single thing for the front suspension. I upgraded where I could and added adjust ability where necessary. Theres some Cusco and Tanabe here and there but I have been continually impressed with the quality of t3 components. They overbuild, use high quality alloys, solid machining and I like that they are made in America with domestic customer service department. JDM bling gets points at NOPI but if I need something replaced by the next day i'd like to have that as an option.

Schroth Pro racer 6 pt harness. I actually got this as an accident when guy at the local porsche shop did the bait and switch. I went in to buy the clubman which is about half the price of the pro racerII and he gave me this one, charged my card for $600 and I was home before I realized what had happened. Ive been meaning to exchange it as they said they would but at this point im thinking i can chalk this up to spilt milk.

AEM fuel rail to tie into the planned fuel system, I want to keep the sizing consistent and minimize the need to use adapters from -AN to NPT or BSP wherever i can. the bonus with the AEM rail is it comes ported for Fuel pressure gauge and the same 6-an size as the rest of the system.. more on that as it comes..

Replacing the AEM ecu with a OEM honda one, they do more than fine on track and theres no need to tune them and you'll never have weird start up issues and mid throttle response issues, plus i get to sell the AEM one.

Since I decided not to use the OEM fuel tank with the internal fuel pump I stepped up too a BOSCH high performance 044 pump its 160-220 LPH@ 5 bar. This is actually the same pump used on current indy cars, many e30 m3 racecars use thse pumps too so its just about perfect for the f20c. No overkill I just dont want any fueling issues. Best part is I was able to get it with -6AN fittings installed, and since its an inline external pump it will be easier to mount and wire. im likely going to have a shielded cubby space welded under the 4 link specifically for this. Next too it is a BOSCH inline filter. These were made specifically for the '79 Mercedes 450 they are again in line style and filter down to 4 microns; even with that capability their girth allows them to still flow extremely efficiently. They actually use these as the filter element of porsche cup cars and on Indy lites. The thread inputs are m12x1.5 and I conveniently happen to have some m12x1.5 to -6AN earls fittings leftover from my NSX oil cooler debacle, so that worked out nicely. I did buy 4 of them since ill be running a brand new fuel cell with closed cell foam. They've been known to shed bits for the first year and clog filters pretty quickly. ill just have too keep and eye on it and replace as necessary.

Next to the pump above are the SPA technique gauges. Ive been eying these for some time, they are designed in the UK but assembled here in the USA, similar to STACK you'll see them used by privateer teams in some bigger racing series, i even recently spotted them in some picture of a couple GTR's and RX7 at Tsukuba. I've had Greddy, Defi, Apexi, HKS, Omori in the past but this time around I wanted something different.

Seems like the trend now days is for Japaneses manufactures is to lock you into buying a brain then piece on gauges and sensors. Before you know you easily spent $1300+ on a pretty basic set that can only run proprietary sensors and has ZERO English support. Shelf life for any of big JDM gauge lines seems to be around 2 years until they move on to another software driver and you outta luck unless you upgrade everything. This means by the time we get them in the US and the US branch of the company figures out how to market and sell them they are halfway through their supported (in japaniese only) shelf life.

I like that these are no nonsense two function display per gauge. They can be programmed to drive external warning lights and beepers at triggers which is a must when on track with you helmet on. They came with all the sensors required and have a nice substantial feeling to them, they also match the s2k gauge cluster color perfectly; not that i actually give a shit about that type of thing.

|

| water temp/fuel pressure |

For the brakes I've picked up some straight forward stuff. my current idea is to leave the OEM GTS brakes up front and put some pads decent fluid and lines. I rebuilt the calipers and am going to give this set up a chance. For the rears I got the AJS ears and adapters to run the OEM calipers (also rebuild) on a larger (thicker) s14 disk. Rears will obviously also get some upgraded pads and lines. The weight im thinking the car will be around seems like this set up will be sufficient, But who knows. I may end up with FC calipers or Willwoods in the long run; the investment in Pads lines and brembo blanks is worth it too me to judge for myself if I actually need more stopping power.

People tell me all the time how bad their NSX brakes are. I actually own a BBK for mine that's just sitting the a shelf because i've found the OEM brakes to be more than adequate. So much so i'm actually down grading the pad compound from HC+ Project Mu's because they are too touchy. I keep going back to Porterfield R4S all around or an R4S/S4 compound stagger. They are not really bitey but super linear in all heat conditions which suits my style. They seem to last forever, are quiet and have good rotor life. Also made in the USA. Im going to run heat stickers on the caliper to get a good idea of whats going on and decide from there. Also ARP wheel studs and steel Work lugs for the option of running spacers as needed.

Heres the mocal 13row with thermostatic sandwich plate. I plan on bracketing it next too or in front of the radiator depending on how it all shapes up. Surprisingly I don't see many s2ks running the track with oil coolers too often. I have no idea why not but its a good cheap insurance policy out in the California desert in August. I have to get another filter adapter since this one didn't fit but the plan is to run the OEM water cooler along with this air element. I'll seal it all off on the induction side and am working out some ideas on how to run a low pressure draw through set up. These type of things depend on other stuff but ill do my best to make it happen.

Speaking of cooling I got two radiators that im potentially going to use. One is a Mishimoto 'race' application. Its the biggest and best of the 3 they make for the 86, it came with the car and it the larger option of the two i have but the intake and return ports are on the wrong side for the motor for the f20c. Ill have to get cross over pipes made and probably some support brackets to run it. My other option is an EK9 type R civic KOYO race radiator.

Its 4 inches less wide than the Mishimoto but the bungs are on the correct side. Apparenty the width being less is a good thing, it allows the intake tube to the throttle body more room for a straighter path which reduces air turbulence. Either way, this or the Koyo, im going to have to have some aluminum coolant lines made since theres really nothing OEM that fits the bill for this problem. I bought an s2k Koyo originally but found that its too tall and wont clear the hood. Since theres no room for a v-mount ill just go with the simpler solution.

Shorter is better as far as pipe length in which case the Koyo looks like the one ill use, I just have to get over myself and years of shit talking half-size radiators.

Even though this isnt technically one i feel i've talked myself into a corner... but now im thinking about it the koyo width should fit perfect with the oil cooler slotted next too it. Either one of course will have an aluminum overflow tank and sit next to a Radium catch can. (not pictured)

First thing that i knew it needed was a new clutch, I picked up the Science Of Speed sport clutch and ultra light STU forged fly wheel. This one is 8.5 bs compared to 14lbs for oem. Since it reciprocal weight that's equates to a HUGE savings over the stock set up and should technically be a tad easier on the rear end.

I have spent a small fortune with SOS on NSX parts over the years. I actually have a very similar clutch and Fly wheel combo in my NSX. It was nice to find out that they R&D and produce great stuff for the s2k too so this purchase was a no brainer. Again Its incredible how much lighter this stuff is compared to my used worn down OEM fly. obviously new oem bearings and clutch master stainless line and slave to go with it.

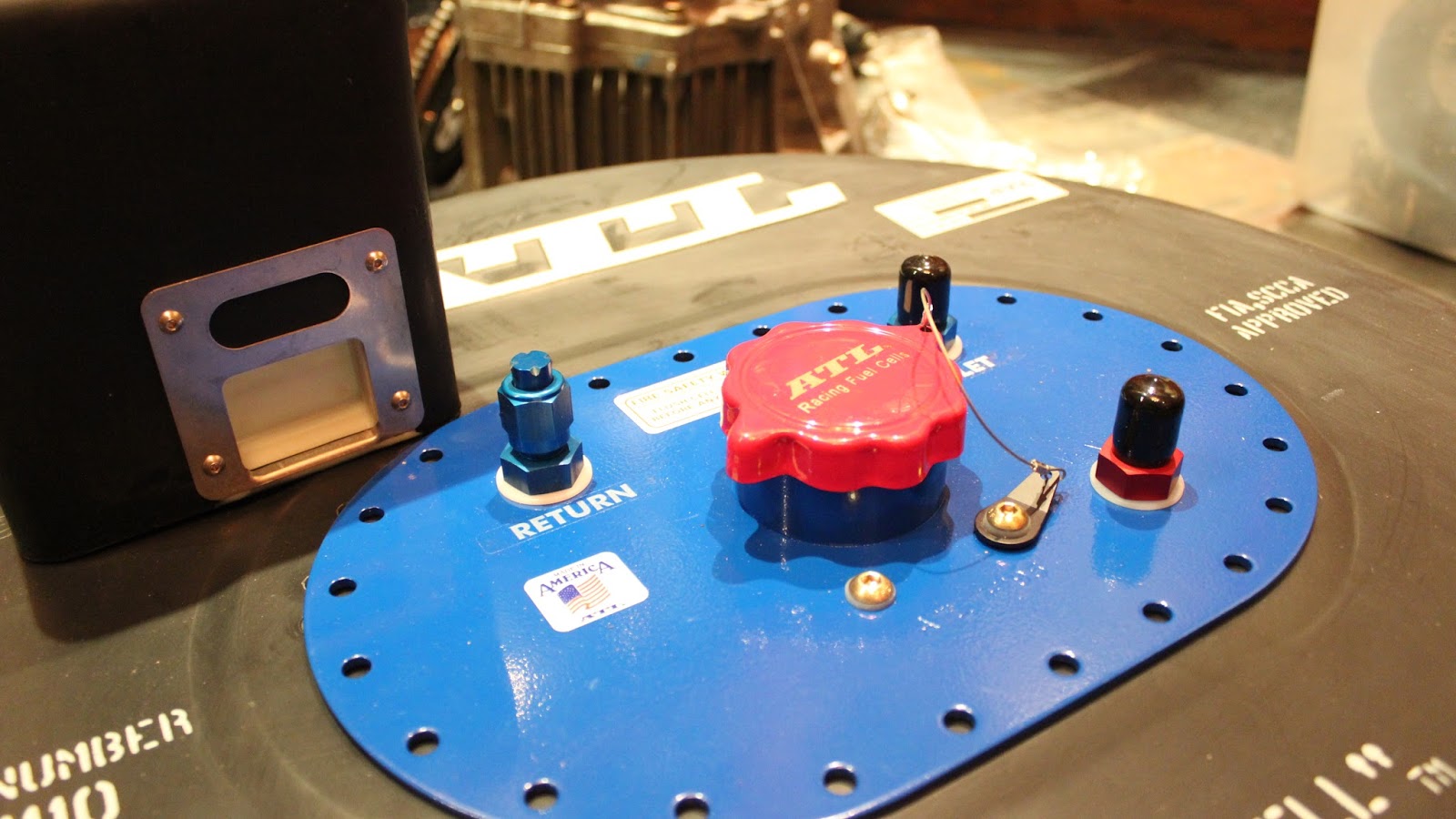

Below is my solution too the shitty fuel lines the car came with, its also a fix for the inherent fuel starvation that comes built into the stock tank design at anything under half. This is the 12 gallon 'well cell' from ATL I also picked up an inbladder trapdoor sump tank. This one actually fits perfectly in the spare tire compartment of the 86 and is SCCA and FIA compliant.

I went through many days and nights of research looking into fuel sump set ups. The cost and hassle of 3 fuel pumps, a sump container and all the ancillary wiring and plumbing didn't add up too me. It seemed mega overkill for a OEM ecu running an NA 2.0 motor. i cam across a MG racing website where some old Brits figured out if they just adjusted the fuel return line to just dump directly the top of the baffled 'trap door' sump they'd always have a direct supply of fuel dumping right next to the pick up with no where else to go. In addition to simplifying everything, you maintain a closed system inside the bladder itself without the need of multiple pressure pumps. Its not a perfect solution but a clever one i plan on stealing.

again -6AN for fuel line consistency comes with flip over protection valve and a provision to properly vent the fumes. For now I left it pretty bare bones. Once I figure out the trunk set up ill order or have fabbed a filler neck extension that wont interfere with the GT wing placement i plan on running.

An added bonus to running a fuel cell is that i can weld/rivet shut the OEM fuel door and not have to run a cable popper into the cabin. Stuff like that is subtle and a perfect example of less is more.

Below is a pic of the fresh cross member I needed. Took a few hours of wire wheel cleaning but its ready to be correctly notched to be used in conjunction with the JSP f20c swap kit (itll get repainted after the welding). I ended up getting the for free off of a tip from Art. I drove to a sketchy neighborhood in Long beach where i was to pull it out of a car siting in some weeds in a guys back yard, i was about to bail on the whole thing when a loc'ed out homie was walking me into a back ally to get to the car..

Long story short, guy ended up super cool helped me take it out in the dirt and heat then refused any of the money i was trying to give him for it. It was humbling, props to him.

I also picked up some Cusco motor mounts only to find out that they lower the motor by 20mm. Thats good for anyone with a 4ag or an 20v but bad for anyone with a f20 like myself. If i tried to use them the motor wouldnt clear the steering rack. I figured this out too late but early enough to source and order some discontinued TRD mounts. They are yet to arrive but hopefully will be here soon. I also grabbed some delrin steering rack bushings for the re install.

When taking the exhaust off a few days after I got the car all I had to do was wiggle it around a little and it snapped off right at the OEM 2 to1 collector. I knew it was cracked or had a hole but it was so rusted so bad it crumpled like aluminum foil. After talking to some honda people I found out that the ap2 header has a wider runner ports and is slightly more efficient @ mid and upper revs. Its OEM quality and you can typically find them for a smoking deal. This particular one is off an 06 that the guy turboed at 5k miles. Its practally brand new and had been sitting in a garage waiting for me to buy it for 10 years.

Maybe going to ditch the heat shields when its time to go on the car, gotta see how it sits. New gaskets and 02 sensor waiting too.

speaking of which, as i go ive been buying new OEM gaskets, stoppers, sensors and cyls. The motor is getting a pretty through refresh before it goes back in. Im doing pretty much everything but the head gasket leakdown revealed healthy compression across all 4 cylinder.

The block got a overdue cleaning too, never mind the ugly valve cover. This is only temporarily on the motor until its safely back in the car and I can swap on the real one with out damaging it. Also got a sweet Mugen oil cap and added Phenolic gaskets too where applicable to keep intake air temps down.

Pre oilpan removal, that will be taken off to be notched to fit the crossmember and cleaned before its reinstalled too,

Pan removed.

awaiting parts. Runfree bumper peeled and back to white and sitting in the background

Intake manifold remove disassembled and cleaned, it was NASTY from all the ap1 blow by from the crank vent. I replaced or will replace most of the sensors for new OEM ones

refreshing valve cover.

aircraft remover-ed the OEM wrinkle finish..

Considered leaving it raw. I even cleaned it up and clear coated it but it looked sorta cheap. I didnt take any pics like that but you can get the idea.

Black wrinkle finish think fits the build much better, looks OEM

I can't say 4:15am was the right time to read this entry but It's hard to get pulled into the details one after another. Have my attention now.

ReplyDeleteGorman Rupp Pump Parts - Need help picking the right Trash pump for your application? Mosherflo Pumps in Houston provide ranges of Gorman Rupp pump parts, trash pumps in Houston. Contact us at 281-800-7867.

ReplyDeleteDurco Pump Parts

Gorman Rupp Pump Parts

Goulds Pump Parts