Progress has been slow on the 86. Basically I am at the most labor intensive point where everything that needs to get done just takes tedious, repetitive, man hours to do. It is easy to lose sight of the end goal when you are mired in the 90th hour of grinding, wire wheeling and dental scraping sealant out of from every nook and crack. Its slow and deliberate work, but as important to the final outcome as everything else.

..it is like an uphill race; slow going until you get to the top and then its all downhill from there. Hopefully.

There have also been other things that have distracted me from focusing on the build full-tilt. Trips, work and other non-ae86 race car expenses (cough, new NSX motor, cough cough..) which have come in waves.

Its especially hard to get motivated to drive the 45 mins to angle grind until midnight after working a full 10 hours at my day job... this summer heat hasn't helped either.

It took a concerted effort to get everything refocused and back on track. I set a goal when I started that it would be near done in 'the fall'. Still trying to stick to that.

Like I was saying, much of the last month or so has been a blur of scraping and grinding.

It's messy, it's LOUD, it's smokey and it makes your finger tips buzz for hours.

|

| Bless this mess..i guess |

You may remember from previous posts that the majority of the under sealing was blasted off at the media shop, but the real PITA spots remained. After trying a verity of methods with varied results, we concluded that the best way was to select a section to work on, around a 16"x10" spot, and stick with that section ONLY until it was done and clean as a whistle. You can easily bounce around from spot to spot on the underside for hours and hours, then step back and literally see zero signs of progress. It feels like a never ending bowl of spaghetti; you can eat and eat and eat and never make a dent.

Step 1: choose a spot

Step 2: wire wheel and get it down at least too some metal is showing.

2a:

|

| The red powder is the blasting media coming out of the rails when they get whacked |

Step 4: Use a torch to heat up the area. You have to work in

small sections and try to avoid breathing the smoke that billows off.

Step 6: move on, and on and on...

Depending on what part of the car you are working on, how much sealant and how many different tools you'll use, I would ball park about 2 hours per section if its going easily.

A section like this, though, is going too take you all night...

Progress comparison shots. Here's the driver's side front wheel well..

Sealant in removal process.. You can see the rust spot has already been cut out.

Another HUGE section was the rear section under the 3rd member. It had the most left over under coating because the differential was in the way during media blasting.

Reminder of what we were up against:

|

| **Shudders** |

And after days and days of work we were finally getting somewhere. You'll notice in the upper part of this picture that there are nut-tab provisions for the fuel and brake hardlines...

|

| Mid-prep |

|

| Also removed were any unnecessary brackets and backing plates |

Detail of a removed nut-tab grinded down.

|

| looking down chassis from the passenger side |

Since it had been a few months since the media blast, you can see some flash rust forming from the humid summer, this is normal for untreated steel. It will be taken care of just prior to rust coating and sealing the underside but i'm waiting until the metal working is done. As of now there are a few last bits to go and some 4-link fabbing. I want to avoid painting things just too grind them away again. More on the prepping and sealing as it comes; hopefully not too long away now.

Full underside shots, maybe 100+ man hours of work between three people. Shout out to my brother too for coming out and giving me a hand when on summer vacation.

|

| Dont mind the abomination of a trans tunnel, it will be gone soon. |

Holes were drilled down along the pinch seams, these started in-line with the front strut and went all the way back too the rear cups, aircraft rivets were then knocked into the hole.

|

| My bro with the japan-san head towel |

|

| Maybe 100+ in the shop that day |

|

| detail of some rivets pre-smashing with a bucking bar |

This was followed down both sides of the car..

|

| pass rear |

The process took quite some time and it may be over-kill, but it's definitely awesome.

Next was something I have always wanted to do since owning track car after track car with beat up and destroyed jacking points. When I got the NSX, I realized how clever the engineers were to build into the chassis beefed up jack point provisions. It probably had something to do with the aluminum chassis, but I wanted something similar on this car. Art cut some tube length ways and fit it over the OEM jack provision and welded it on.

Welded beads at the ends were added as an extra safety provision too keep the car slipping forward or backward off jack stands.

Art continued on with some more rust patching. This spot was the driver's right, floor side next too the door frame. The area above it was the old box that was used for the front legs of the old rollcage that had been cut out. These will be cleaned up as the new cage begins too take shape.

USDM side marker lights deleted too. Removing these will clean up the look but also simplify the wiring harness that will need to be built.

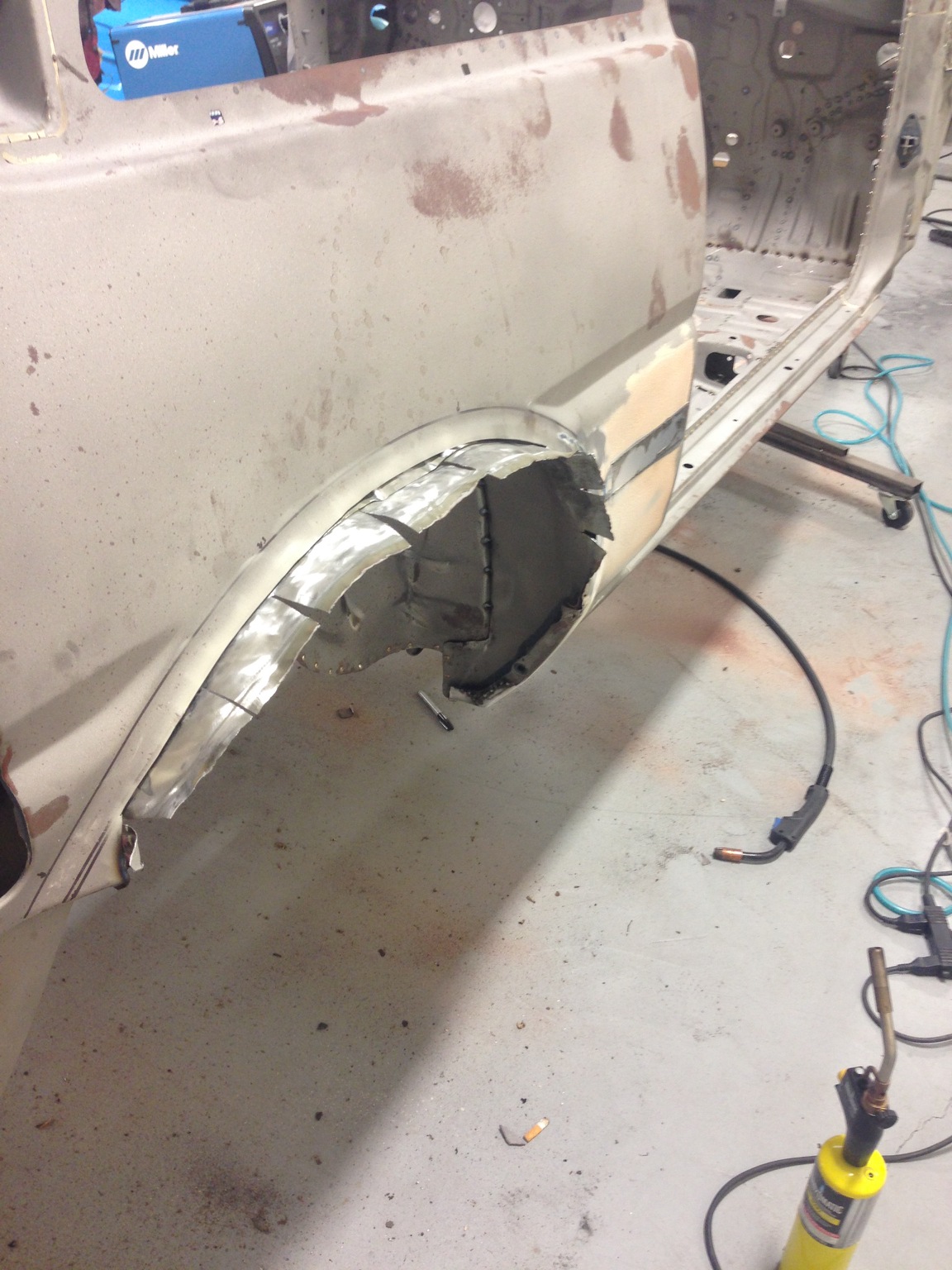

The rear flairs showed up so it was time to cut the wheel wells and fit them. People usually bolt on flairs over the stock body but that negates the point of flairs- letting you run wheels that would normally be too wide too fit or just widening the wheelbase as much as possible.

The rear fender was traced and cut, along with it the hack job edges and rust that was there before.

The inner lip is then cut and bent up. Typically, at this point, the inner lip is then welded to the outer edge and its called 'done'

Art took a look and wasn't happy knowing that he could deliver something better. He then cut off the inner edge.

|

| tracing the space, an awkward 3d shape. |

|

| refinement |

|

| transfer to metal |

|

| Hes got all the cool tools |

|

| Test fitting |

|

| final tacking and test fit |

|

| side view |

|

| Top down, trimmed and finished. |

|

| flair mocked onto the car. And the other side |

As the chassis work was taking place, K1 was assembling my new rear end so I would have it back in time for the equal length 4-link phase. Everything was checked, verified and all wear items replaced. It came back looking similar to when it left, but inside all the parts that will keep the car on track after they'd seen the maximum amount of abuse.

You can see the ARP wheel studs and Cusco 5th-link bracket welded on. The only hint that this isn't your typical plane-jane guts GTS rear were the silver axle ends. Dust shields will likely be coming off after I test fit the s13 rear rotors.

In other parts news, I have decided that I need something special for the seat. I had looked around for a few different options from some pretty cool small batch companies but couldn't find anything that really lit a spark. Every seat I sit in now I subconsciously compare to the one in my NSX. Its PERRRFFEECTTTT for my body size; comfortable and safe. I even thought about cannibalizing the one out of the NSX but had second thoughts after remembering how difficult it had been to get its seating position juuust right.

That's when it struck me that I should just search for another one. After scouring around for a while I came across what was a 'meant to be' situation. I found one in the 'rare in america' smaller size (like my other one) but this one out of a factory Porsche cup car. The very same type of car that I had alluded to earlier in the blog and credited with inspiring the mindset behind this build.

These seats are made especially for Porsche with specific markings and the ever so cool Porsche badge stitched into the backing. It's got patina, but I think it wears it handsomely.

|

| King of the parts pile |

|

| I love the profile of this seat |

Going to end this picture with a picture of my NSX. Deal with it.