Work has been totally batshit hectic and on top of that had too move houses--- and on top of that had about a billion other things to attend too. The only reason I'm able to sit at a computer an write up another entry is because things are thankfully finally starting to calm down again. Internet is up at my new place and theres no more boxes to move or pictures to hang so I feel like i should get post up before I forget anymore details...

As I was saying on my last post were on the tail end of the chassis repair and moving swiftly along into the fabrication portion of the build. This doesn't just mean cage fabrication but all the little things along the way. We'd already started and finished a few of these smaller projects along the way but it was almost more so we could have some sense of progress while the labor intensive stuff lumbered along at a snails pace. Now with the 'big stuff' being mopped up its nice to jump into the rest of it and get excited again.

A perfect example is this lower window support. If you remember a few posts back we'd removed all the partitioning between the cabin and the trunk along with the rear speaker tray and trunk hinges. To recap; they were just dead weight since the trunk is to be totally removable from the car for reasons of rear wing badassery.

Instead of just leaving it a floppy-flemsy cross piece for the rear window to cling too Art fabbed up this totally awesome gusseted support. Stuff like this takes time and know how to get fit right, you'll notice the slight arch it must follow to attach evenly to the OEM metal, killed it.

As we were moving along and prepping the 4 links to go in I almost by chance noticed a rust spot while looking down a hole into the 5th link support.

you can see it would have been easy too miss. This picture was take after we knocked a punch through it to see of it was indeed rusted.

Here (above) is Art trying to determine the extent of the damage...

The affected metal was cut out for replacement..

This part of the chassis deals with quite lot stress due to the nature of the 5-links set up on the ae86- its the backbone of the rear end and accounts for keeping the driveshaft aligned down the center of the car, the whole 3rd member wants to wag left and right as the suspension compresses and lightens under acceleration and braking and this is what anchors the fulcurm that stops it. On top of fixing the rust Art took the chance to make it triple beefy to keep everything stiff as possible

Sitting pretty but not yet welded.. I noticed they actually offer these boxes for sale on the t3 site now. Your welcome world.

Heres a shot of the diff lifted almost into place to verify its alignment

And a detail of the underside before it was welded in. (car is sideways for the picture)

Finally welded into place for its final time

Links installed for illustration.

Then THIS happened, Art came correct and got a lift installed. Its awesome! He's turning into a real shop.

--------intermission--------

After a few short hiatuses for Art to do some high end work on SEMA cars and for me to move my life to a different house, I got a call that my NSX was finally alive and breathing again with the new motor.

Heres a .gif me stoked too see it running for the first time. (SEMA build in the back ground)

-------intermission end----------

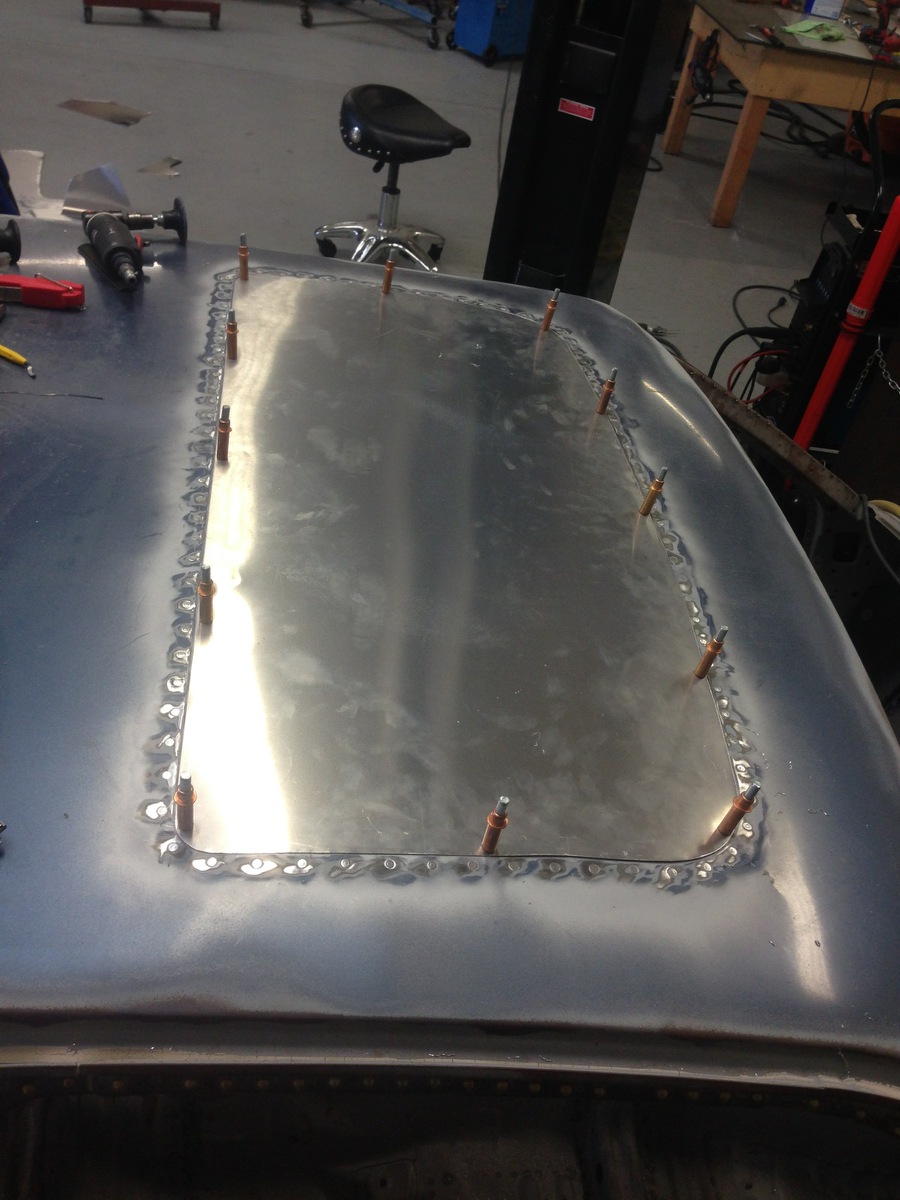

back to the build, plugging some holes... this one was for the brake master cyl. the other holes and trans tunnel will get handled soon.

After poking around some more I found some just forming rust on the rear valance at the back of the car.

After some discussion it was decided that "who need those anyways" the rear valance was cut out as well as the beat up lower part of the spare tire compartment

|

| Note the completely horizontal 5th link, as discussed in previous posts. |

You can see this opens up some interesting aero options.... :]

You may remember that I am going to run a 15 gallon "well cell" thats designed to sit in the spare tire tub. You can see above that the tub was cut out to build a cleaner, flatter surface for it too sit. After looking at this set-up more closely and its potential alternatives (read: $$$) there's a good compromise to be had somewhere in the middle. Utilizing the parts I already own and Arts mad skillz I think were shaping up something that's going to be better in every way, more on this as it comes...

I also went and picked up my Origin 30mm fenders. I ordered these new because I didn't want to deal with repairing a used, fucked up pair. Turns out my 5 month wait for these was in vain because only after I got them to the shop and unwrapped them did I see that they too were cracked and would need repair.

steering rack hitting just under the passenger motor mount

A quick revision later and everything is looking good.

|

| clean welds once again |

|

| in progress |

|

| underside in progress |

|

| finished below |

|

| Smooth as a babies bum, Howard Hughes would be proud |

Im ending this post with some 'blueprints' as Art calls them. They are typically how I communicate ideas about the car when im at work and hes cranking away in the shop.

Whatever, At least *I* think they are helpful.

Until next time!